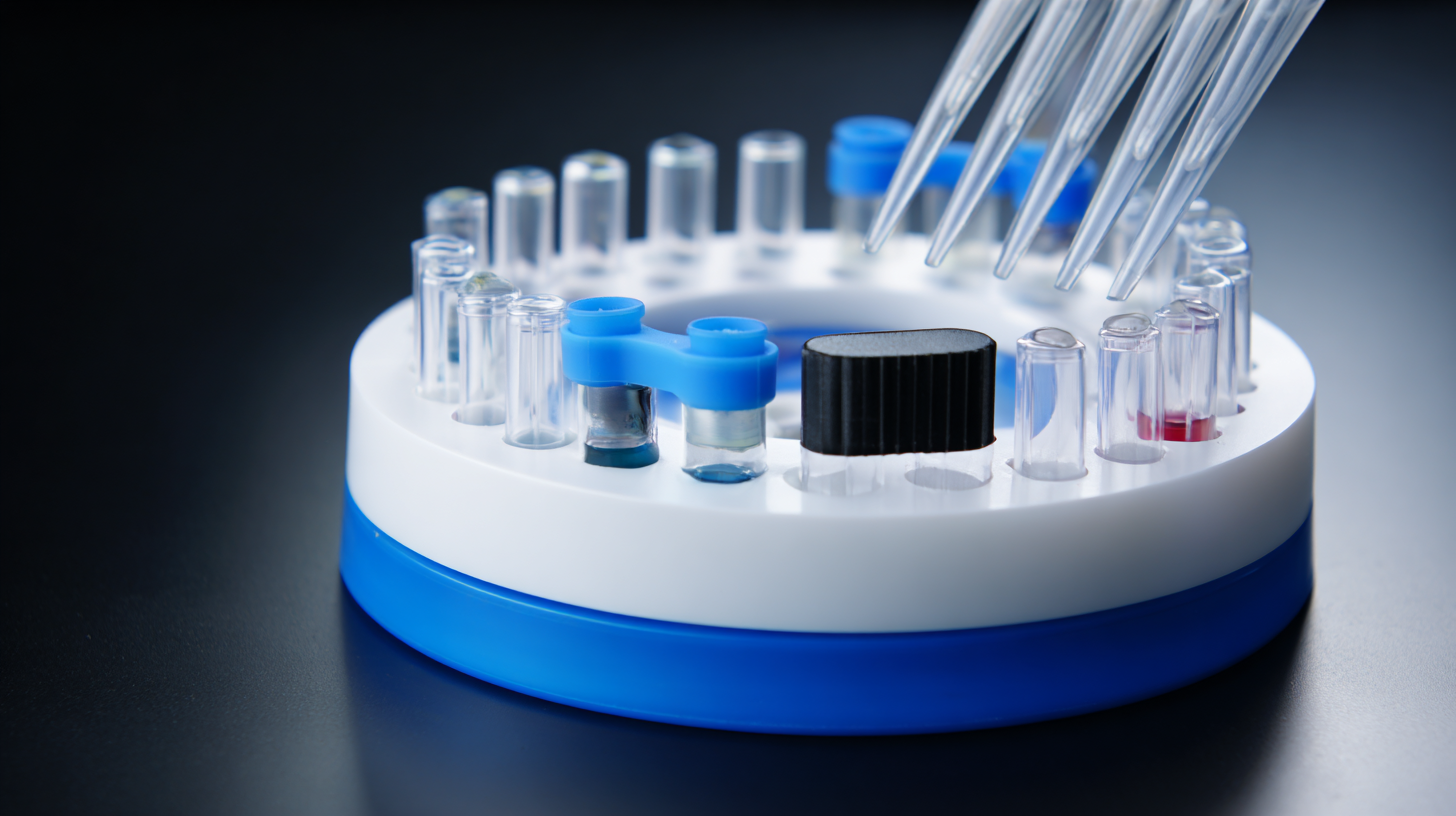

In the ever-evolving landscape of laboratory equipment, the Lab Ptfe Magnetic Stirrer Bar stands out as a pivotal element for achieving optimal mixing efficiency in various scientific applications. Recent industry reports indicate that the global demand for laboratory stirring equipment is expected to reach $2.5 billion by 2025, highlighting the crucial role of advanced stirring solutions in enhancing experimental accuracy and reliability. The unique properties of PTFE, including its chemical resistance and low friction surface, make the Lab Ptfe Magnetic Stirrer Bar an indispensable tool in laboratories across a range of sectors, from pharmaceuticals to food science. As Chinese manufacturers continue to upgrade their quality standards, these stirring bars are rapidly becoming a preferred choice for researchers worldwide, ensuring consistent results and superior performance in mixing tasks.

In the realm of laboratory equipment, the significance of after-sales service cannot be overstated, particularly when it comes to PTFE magnetic stirrer bars. These essential tools are instrumental in ensuring optimal mixing and achieving precise results in various experiments. When purchasing PTFE magnetic stirrer bars, a reliable after-sales service provides peace of mind, ensuring that any issues can be addressed swiftly. This support not only enhances user experience but also boosts the longevity of the equipment, making it a valuable investment.

Good after-sales service includes timely maintenance and troubleshooting support, which is critical for laboratory efficiency. Suppliers who offer extensive warranties and proactive customer service help lab scientists avoid downtime that could affect their research outcomes. Additionally, these services often include helpful guidelines and tips for proper usage and care, maximizing the performance of the magnetic stirrer bars. In the competitive landscape of laboratory supplies, companies that emphasize robust after-sales support distinguish themselves, building trust and lasting relationships with their customers.

When considering the cost of maintenance for magnetic stirrer equipment, it's essential to recognize the significant role these devices play in laboratory settings. A recent industry report highlights that maintaining a magnetic stirrer can account for approximately 15-20% of the overall laboratory equipment budget. This statistic underscores the necessity for effective cost management strategies to minimize operational expenses while maintaining optimal performance.

One key component contributing to maintenance costs is the lifespan of the PTFE magnetic stirrer bar, which is often subject to wear and tear due to constant agitation in various solutions. Experts recommend replacing these stir bars every 200-300 hours of use to ensure consistency and reliability in mixing. Additionally, regular maintenance schedules and the use of high-quality materials can help extend the lifespan of both the stirrer and the PTFE bars, potentially reducing long-term costs. Industry data shows that facilities implementing proactive maintenance practices can save up to 30% on replacement costs over a five-year period, emphasizing the importance of a well-planned maintenance strategy.

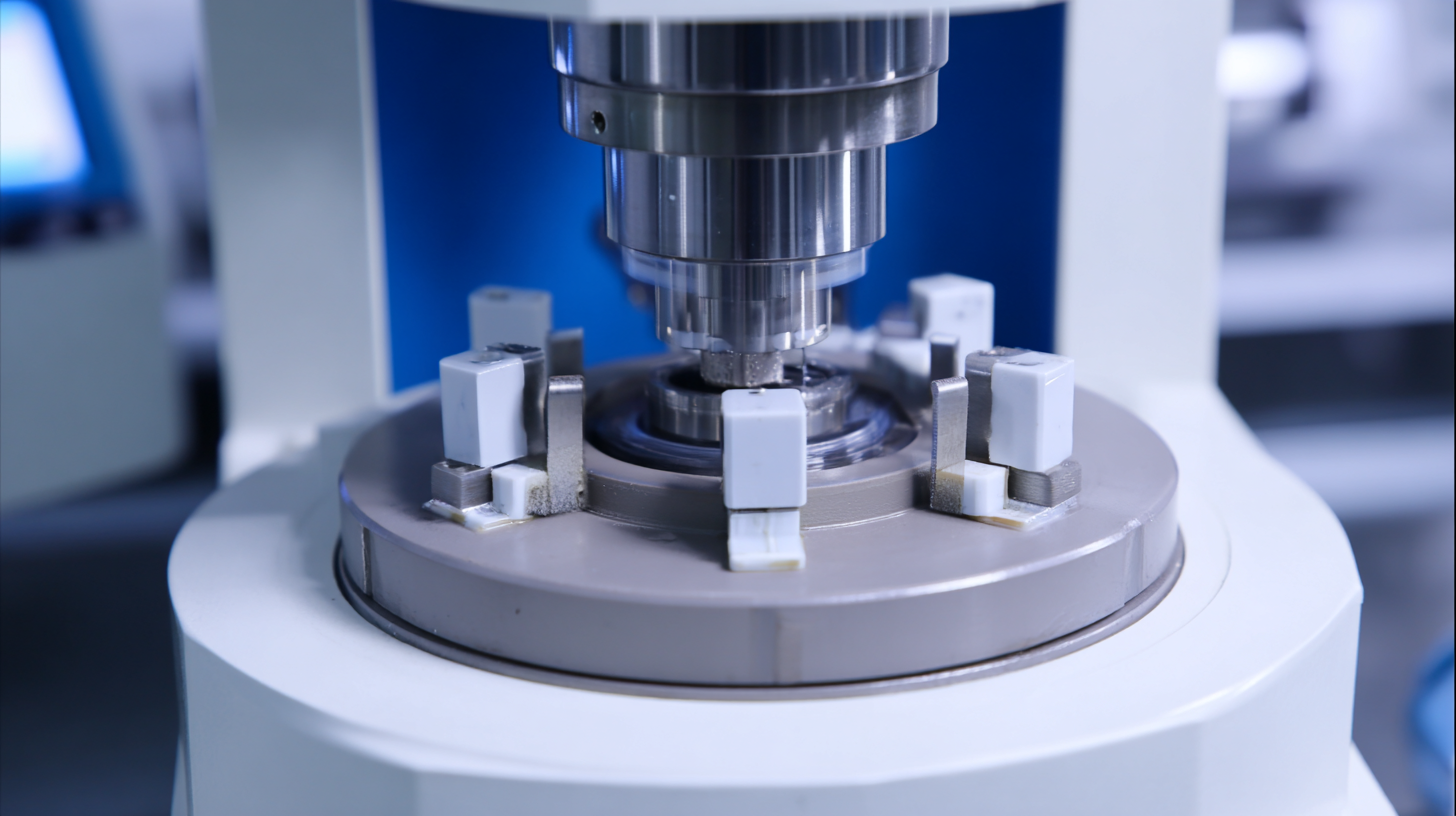

In the ever-evolving landscape of laboratory technologies, innovative mixing solutions play a pivotal role in enhancing research outcomes. The advent of advanced materials and design in lab equipment, particularly in the realm of magnetic stirrers, has transformed how scientists approach mixing tasks. The introduction of high-density PTFE magnetic stirrer bars exemplifies this shift, offering superior chemical resistance and durability. These innovations not only improve efficiency but also ensure the integrity of the samples being mixed, which is crucial in sensitive experiments.

Moreover, the integration of smart technologies into lab mixing solutions is revolutionizing workflows. Features such as automated temperature control, precise speed regulation, and real-time monitoring create a more streamlined and user-friendly experience for researchers. With the ability to save protocols and reproduce results consistently, modern stirring devices elevate the standard of precision in laboratory settings. As the demand for reliable and effective mixing solutions grows, the development of these technologies will continue to shape the future of laboratory practices, ensuring scientists can focus on what truly matters: their research.

| Mixing Technique | Description | Optimal Stirrer Bar Size (cm) | Recommended Speed (rpm) | Application |

|---|---|---|---|---|

| Standard Mixing | Basic mixing of solutions. | 2.5 | 300 | General lab applications |

| High Viscosity Mixing | For thicker solutions requiring more force. | 5.0 | 200 | Viscous solutions in chemical experiments |

| Homogenization | Achieving uniformity in particle size. | 3.0 | 400 | Biological and chemical samples |

| De-aeration Mixing | Removing gas bubbles from the mixture. | 4.0 | 250 | Chemical preparations that require vacuum. |

| Magnetic Stirring with Sensors | Continuous monitoring for consistency. | 2.5 | 350 | Advanced lab insights and analytics |

When working with PTFE magnetic stirrer bars, optimizing their performance is essential for achieving the best mixing results in your laboratory. One key practice is to select the appropriate size and shape of the stirrer bar for your specific application. The length and diameter must align with the dimensions of the vessel to ensure efficient agitation. A bar that is too small may underperform, while one that is too large could create excessive turbulence, leading to uneven mixing.

When working with PTFE magnetic stirrer bars, optimizing their performance is essential for achieving the best mixing results in your laboratory. One key practice is to select the appropriate size and shape of the stirrer bar for your specific application. The length and diameter must align with the dimensions of the vessel to ensure efficient agitation. A bar that is too small may underperform, while one that is too large could create excessive turbulence, leading to uneven mixing.

Another best practice involves adjusting the stirring speed to match the viscosity of the solution being mixed. For viscous liquids, a slower speed may be more effective, allowing for a thorough blend without creating excessive bubbles or foam. Conversely, for less viscous solutions, increasing the speed can enhance mixing efficiency. Additionally, periodically checking the stirrer bar for wear and cleanliness will help maintain optimal performance; a clean bar is crucial for proper magnetic interaction with the stirrer’s base. By implementing these practices, researchers can significantly enhance the effectiveness of their PTFE magnetic stirrer bars.

In recent years, the comparison between traditional and modern stirring techniques in laboratory settings has garnered significant attention. Traditional methods often rely on manual stirring or basic magnetic stirrers, which can lead to inconsistent mixing and varying results. A survey conducted by the Journal of Laboratory Automation indicates that approximately 40% of researchers reported difficulties in achieving uniform solutions with these conventional approaches, especially in experiments requiring high precision.

Conversely, modern stirring techniques featuring advanced PTFE magnetic stirrer bars have revolutionized the way mixing is conducted in laboratories. These stirrers not only enhance mixing efficiency but also reduce contamination risks due to their chemically resistant properties. According to the American Chemical Society, labs utilizing PTFE magnetic stirrers experience a 30% increase in productivity thanks to their ability to maintain consistent stirring speeds and minimize operator error. Moreover, a report from Lab Manager has shown that these modern devices can achieve optimal mixing in less time, often cutting the required mixing duration by more than half when compared to traditional stirrers. This shift towards innovative stirring solutions underscores the importance of adopting best practices to enhance experimental outcomes.