In the fast-paced environment of modern laboratories, efficiency and precision are paramount. Researchers are constantly seeking innovative tools that can enhance their workflows and streamline processes. One such tool that is gaining traction in 2025 is the PTFE stir bars retriever. This versatile instrument not only helps in the efficient mixing of solutions but also simplifies the retrieval process of stir bars, thereby minimizing contamination risk and reducing downtime.

The PTFE stir bars retriever stands out due to its non-stick surface and chemical resistance, making it ideal for a variety of chemical applications. By integrating this tool into daily laboratory procedures, researchers can improve their productivity and focus more on data analysis rather than manual retrieval tasks. This introduction will explore the top uses of PTFE stir bars retrievers, highlighting how they can revolutionize laboratory practices and enhance overall efficiency. Through a closer look at their functionality and advantages, it becomes clear that adopting PTFE stir bars retrievers is a significant step towards optimizing laboratory operations in the coming year.

PTFE stir bars have become essential tools in modern laboratories, offering a range of features that enhance experimental efficiency and accuracy. One of the notable properties of PTFE (Polytetrafluoroethylene) is its exceptional chemical resistance, which allows it to withstand aggressive solvents and acids without degrading. This characteristic not only ensures the longevity of the stir bars but also minimizes the risk of contamination in sensitive experiments. Additionally, the inert nature of PTFE means that it does not react with the materials being mixed, providing consistent and reliable results.

Another significant feature of PTFE stir bars is their hydrophobic surface, which prevents sticking and allows for smooth and efficient stirring in various solutions. This quality is particularly beneficial in applications involving viscous or dense substances, as it ensures thorough mixing without the formation of clumps.

Moreover, many PTFE stir bars come equipped with improved magnetic properties, allowing for stronger retention and control within the stirrer, which further enhances the mixing process. The design and functionality of PTFE stir bars are continuously evolving, making them a cornerstone for laboratories aiming to optimize their methodologies and achieve greater precision in their work.

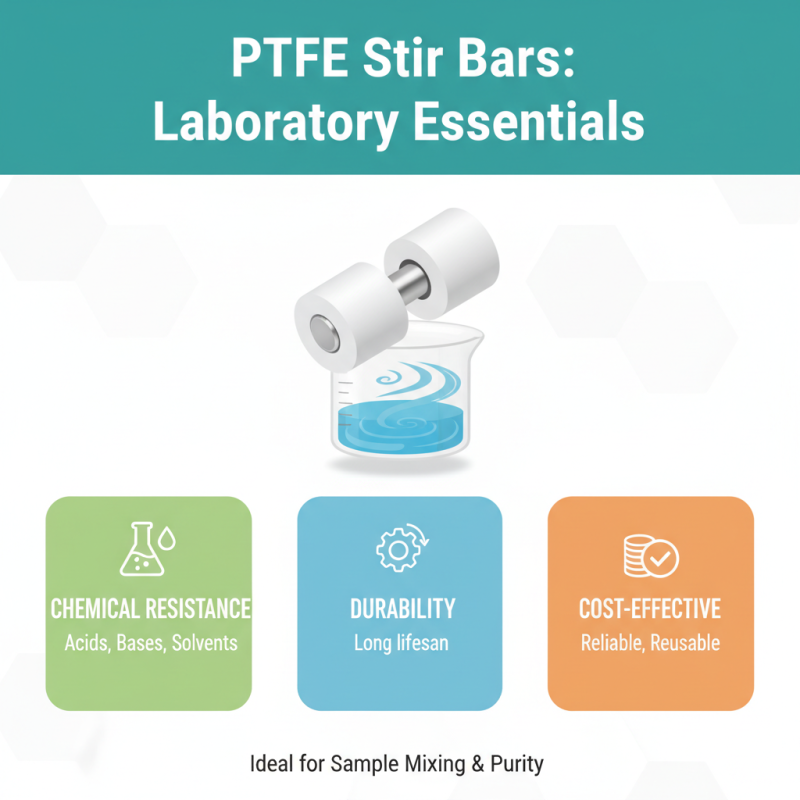

PTFE stir bars have become indispensable tools in laboratory settings, particularly for sample mixing tasks. One of the foremost advantages of using PTFE stir bars is their excellent chemical resistance. Made from polytetrafluoroethylene, these stir bars can withstand a wide range of solvents, acids, and bases without degrading or reacting. This property not only ensures the integrity of the sample being mixed but also prolongs the lifespan of the stir bars themselves, making them a cost-effective choice for researchers.

In addition to their chemical durability, PTFE stir bars provide superior mixing efficiency. The smooth surface of PTFE allows for a better flow of materials, minimizing the risk of snagging or clumping during the mixing process. This ensures a homogenous sample, which is essential for obtaining accurate and reproducible results in any experimental setup. Furthermore, their non-stick nature helps to reduce sample loss, leading to more precise measurements and analyses. As labs continue to strive for higher efficiency and reliability in their processes, the use of PTFE stir bars for sample mixing will undoubtedly play a crucial role in achieving these goals in the coming years.

When comparing PTFE stir bars to traditional stirring methods, several key advantages of PTFE stir bars emerge. Traditional stirring techniques often rely on mechanical devices, such as magnetic stirrers or overhead stirrers, which can introduce variability in stirring speed and might not accommodate all types of containers used in laboratories. In contrast, PTFE stir bars utilize a unique composition that minimizes reactivity, ensuring that samples remain uncontaminated during the mixing process. The inert nature of PTFE makes it suitable for a wide range of chemical applications without altering the properties of the substances being stirred.

Furthermore, PTFE stir bars enhance laboratory efficiency by enabling a smoother stirring experience. Unlike traditional methods, which may require constant supervision or manual adjustments, PTFE stir bars can provide consistent mixing with minimal effort. Their design allows for easier retrieval from beakers and flasks, reducing the risk of spills and sample loss. The durability of PTFE also means that these stir bars can withstand a variety of conditions, including extreme temperatures and corrosive substances, making them a versatile choice for modern laboratory settings focused on precision and reliability in experimental results.

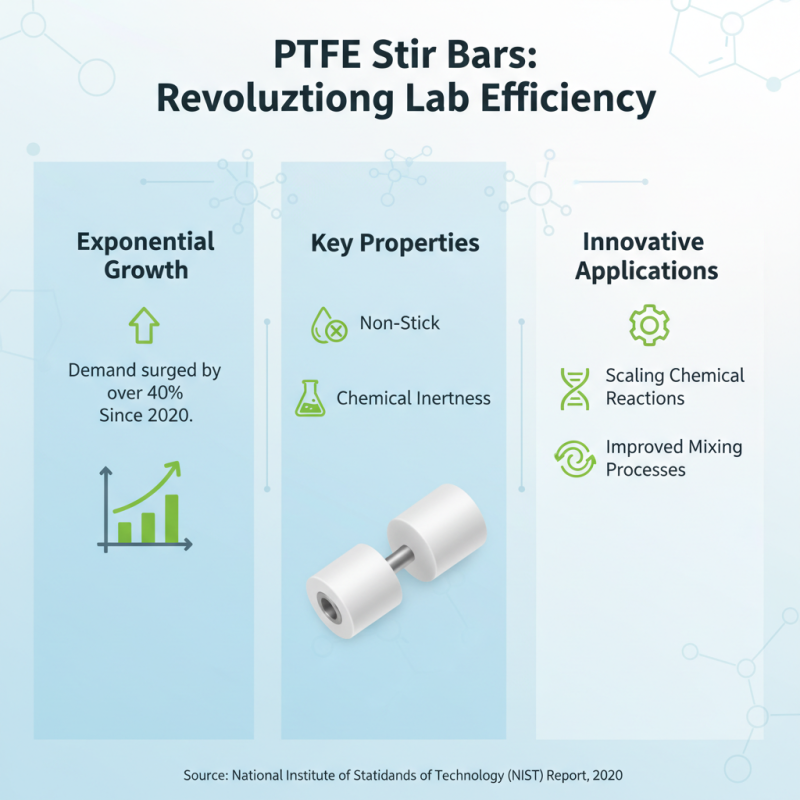

In recent years, the application of PTFE (polytetrafluoroethylene) stir bars in research laboratories has grown exponentially, owing largely to their non-stick properties and chemical inertness. According to a report by the National Institute of Standards and Technology, the demand for advanced laboratory equipment like PTFE stir bars has surged by over 40% since 2020, reflecting their crucial role in enhancing laboratory efficiency. Researchers are now leveraging these innovative tools in a variety of ways, from scaling chemical reactions to improving the mixing processes in complex analyses.

One notable application is in the field of pharmaceuticals, where PTFE stir bars are utilized to facilitate the synthesis of compounds by providing an efficient and uniform mixing of reactants. This not only accelerates reaction times but also yields higher purity products, crucial for rigorous industry standards. Additionally, in material science, PTFE stir bars are applied in the development of advanced composites, ensuring that materials are homogeneously mixed, thus enhancing their mechanical properties significantly.

**Tips:** When using PTFE stir bars, it's essential to select the correct size for your vessel to ensure optimal stirring efficiency. Additionally, ensure that the stirring speed is sufficient to achieve a uniform mixture without causing cavitation, which can lead to inconsistencies in results. Regular inspection of stir bars for wear and tear will also prolong their effectiveness and maintain laboratory standards.

Proper maintenance and utilization of PTFE stir bars are essential for maximizing laboratory efficiency in 2025. First and foremost, regular inspection is crucial. Before each use, stir bars should be checked for any signs of wear or damage, such as chipping or discoloration. These imperfections can affect their performance and lead to contamination of samples. Moreover, using appropriate cleaning methods, such as rinsing with compatible solvents and avoiding abrasive materials, can prolong the life of the stir bars while maintaining their effectiveness.

Another best practice is to ensure that the stir bars are adequately sized for the containers used in experiments. Oversized stir bars can lead to inefficient mixing, while undersized ones may not generate sufficient agitation. Additionally, utilizing the correct stirring speed is vital; overly high speeds can result in vortex formation, causing stir bars to leap from the bottom of the container, reducing mixing efficiency and potentially damaging both the stir bar and the container. By following these guidelines, laboratories can harness the full potential of PTFE stir bars, optimizing their workflows and ensuring consistent results in research and experimentation.

| Use Case | Efficiency Benefit | Best Practices | Maintenance Tips |

|---|---|---|---|

| Homogenous Mixing | Improves sample uniformity and accuracy | Select appropriate stir bar size for vessel | Clean after each use to prevent contamination |

| Temperature Control | Enhances reaction conditions stability | Monitor temperature during stirring | Inspect for wear to maintain performance |

| Chemical Resistance | Ensures integrity in aggressive environments | Use in compatible solvents only | Store in a cool, dry place when not in use |

| Time Savings | Reduces overall experiment preparation time | Optimize stirring speed based on solution | Check for physical damage regularly |

| Versatility | Applicable in various laboratory applications | Choose the right stir bar for each task | Rinse thoroughly after mixing different materials |