Choosing the right PTFE stirrer bearing is crucial for various applications. Many factors come into play when selecting the perfect bearing. The PTFE stirrer bearing's specifications greatly influence its performance and longevity.

Consider the specific environment where the stirrer will operate. High temperatures and corrosive materials can affect its functionality. Moreover, the size and fit of the bearing matter. An improper fit can lead to operational issues. Many users overlook this detail, impacting efficiency.

It's essential to evaluate your needs thoroughly. Think about the stirrer's intended use and its load requirements. Small mistakes in the selection process can lead to inefficiencies or even equipment failures. Ensure you make a well-informed choice to enhance performance.

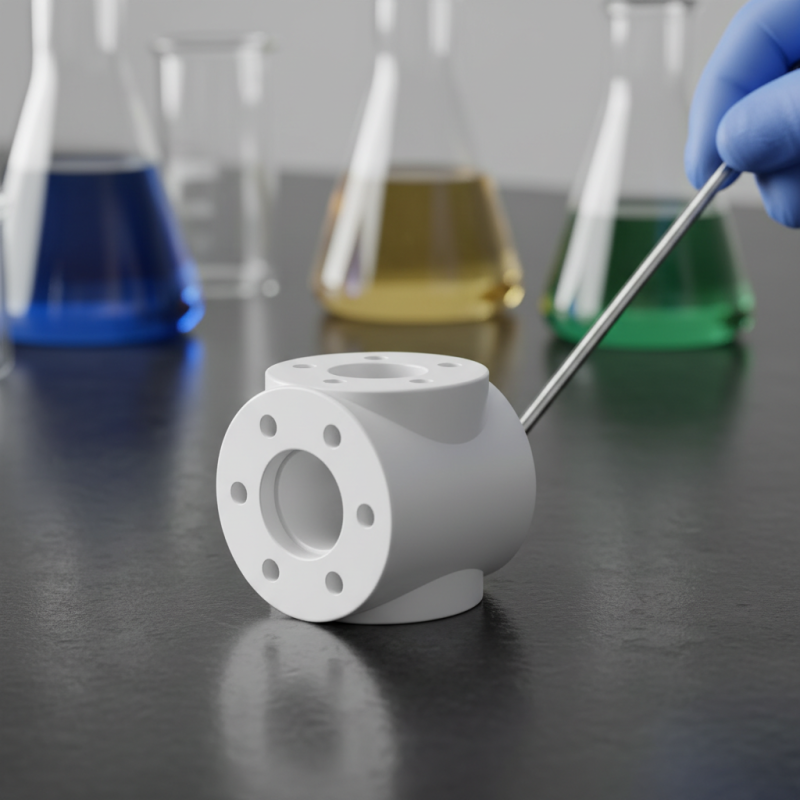

PTFE stirrer bearings are vital components in various applications. They are known for their excellent chemical resistance and low friction properties. These features make them ideal for industries like pharmaceuticals and food processing. When choosing a PTFE stirrer bearing, it’s essential to consider the specific requirements of your application.

For instance, the size of the stirring equipment matters. If the bearing is too small, it may wear out quickly. On the other hand, an oversized bearing can result in inefficient stirring. Additionally, the surface finish of the bearing can impact performance as well. A smoother finish generally leads to better efficiency.

In applications involving extreme temperatures or aggressive chemicals, it's important to evaluate the bearing's limits. Some bearings may not withstand high temperatures. Regular maintenance is also crucial to ensure longevity. Over time, even the best bearings can degrade. Reflecting on your specific needs is essential when selecting the right PTFE stirrer bearing.

When selecting a PTFE stirrer bearing, several key factors come into play. The size and shape of the bearing matter significantly. Ensure the dimensions fit well with your stirrer design. This prevents unwanted friction or wear. Additionally, consider the load capacity. The bearing must withstand the stirring action without failure.

Material quality is another crucial aspect. PTFE offers excellent chemical resistance. However, not all PTFE is created equal. Look for high purity in the material. This prevents contamination in your processes. For specific applications, temperature tolerance is vital. Verify the bearing can perform at high or low temperatures.

Lastly, think about the environment where the stirrer will operate. Is it clean or dusty? Will there be exposure to corrosive substances? These factors will influence your choice. A proper selection may not be easy and often requires trial and error. Keep documentation and feedback to refine your choices over time. Each application might bring new challenges. Adapting to these changes is essential for success.

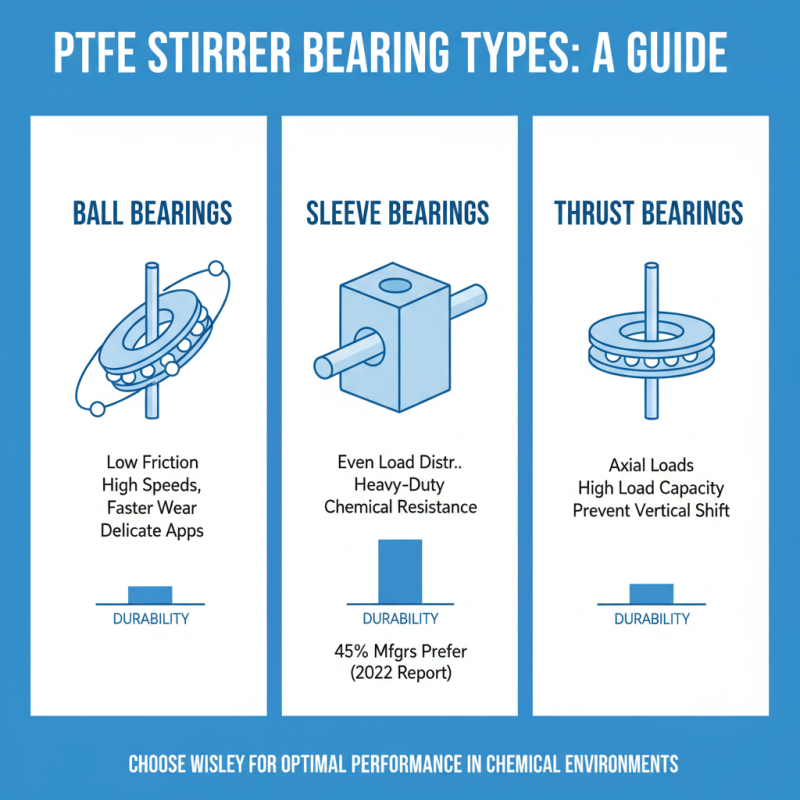

When selecting a PTFE stirrer bearing, understanding the types available is crucial. Common designs include ball bearings, sleeve bearings, and thrust bearings. Each type has distinct properties. For example, ball bearings offer lower friction but can wear faster. Sleeve bearings often provide better load distribution, making them suitable for heavy-duty applications. According to a 2022 industry report, over 45% of manufacturers prefer sleeve bearings for their durability in chemical environments.

Different materials also affect performance. While PTFE is chemically resistant, variations exist. Some formulations incorporate fillers for enhanced strength or conductivity. This can influence the bearing's ability to perform under stress. Data suggests that 60% of failure in stirrer applications is related to material choice. Choosing the right PTFE formulation is essential, and many users overlook this aspect.

It is important to consider the operating environment. High temperatures or aggressive chemicals can compromise performance. An analysis showed that 30% of stirrer failures were due to thermal degradation. Therefore, researching specific application requirements is vital. Rushing to select a PTFE stirrer bearing can lead to significant issues down the line. Make informed decisions to avoid costly mistakes.

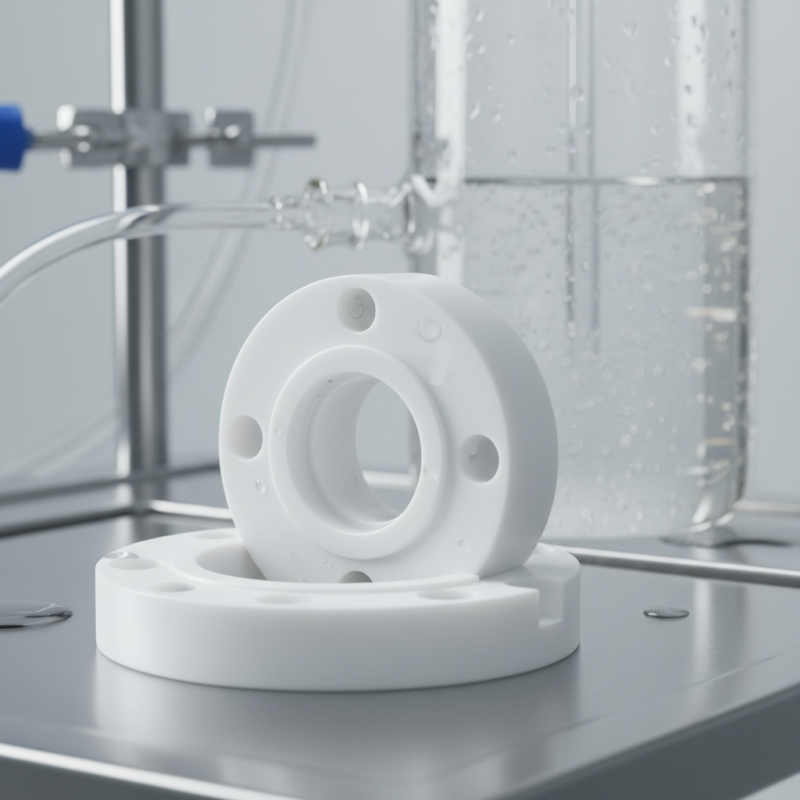

Choosing the right PTFE stirrer bearing requires careful consideration of several factors. Size is crucial. If the bearing is too large or small, it will not perform optimally. Measure the internal diameter and length to ensure compatibility with your equipment.

Specifications play a significant role in the decision-making process. PTFE bearings come with various load ratings, temperature tolerances, and chemical resistance levels. Identify the conditions your stirrer will face. Will it endure extreme temperatures? How about exposure to corrosive substances? Matching specifications to your needs will enhance performance.

Tips: Always double-check the manufacturer's guidelines. Small discrepancies can lead to significant issues. Consider consulting with experts who can provide tailored advice. Test a few options if possible. It's better to invest time in research than to deal with recurring malfunctions later on. Don't overlook compatibility. Not all stirrer bearings are suitable for every application. This could lead to poor efficiency and premature wear.

| Dimension | Specification | Compatibility | Performance Factors |

|---|---|---|---|

| Outer Diameter | 20 mm | Standard stirrer shafts | Optimal for low viscosity fluids |

| Inner Diameter | 10 mm | Compatibility with standard motor shafts | Suitable for high-speed applications |

| Length | 50 mm | Fits most laboratory mixers | Consistent stirring efficiency |

| Material | PTFE | Universal application | Chemical resistance |

| Load Capacity | 5 kg | Use with medium viscosity materials | Durable under consistent use |

When it comes to maintaining PTFE stirrer bearings, regular upkeep is crucial for longevity. PTFE is known for its low friction and excellent chemical resistance. However, even durable materials need attention. A study by the American Society for Testing and Materials found that proper lubrication can extend bearing life by up to 40%. This means using the right grease on a consistent basis is essential.

Inspecting the bearings for wear is equally important. Signs of wear, like discoloration or rough surfaces, indicate that it's time for replacement. Keeping a maintenance log helps track condition changes over time. According to industry experts, 30% of bearing failures relate to poor maintenance practices. Cleaning the area around the bearings regularly can prevent contaminants from causing damage.

Improper handling during installation can also lead to issues later. For example, over-tightening can damage the PTFE material. Be mindful of torque specifications during setup. A well-maintained PTFE stirrer bearing should last long, but neglect can cut that lifespan significantly. Regular checks and thoughtful management make a difference in performance.

This chart illustrates the average lifespan of PTFE stirrer bearings based on maintenance practices. Ensuring proper maintenance can significantly extend the bearing's life, leading to better performance and cost efficiency.