In the world of laboratory equipment, the choice of tools can significantly impact the quality of experimental results. Among these tools, the PTFE stirring stick stands out for its chemical resistance and durability, making it a preferred choice in laboratories dealing with aggressive solvents and corrosive materials. According to a report by Research and Markets, the global laboratory equipment market is projected to reach $50 billion by 2025, with an increasing demand for high-performance materials like PTFE in various applications. This highlights the importance of selecting the right stirring stick to ensure the accuracy and reliability of your experiments.

In this guide, we will explore key considerations for choosing the best PTFE stirring stick tailored to your laboratory needs, ensuring optimal performance and safety in your workflows.

PTFE stirring sticks play a crucial role in laboratory environments, particularly due to their unique chemical resistance and non-stick properties. Made from polytetrafluoroethylene, these stirring sticks are ideal for handling a wide range of substances, including corrosive chemicals and viscous solutions. Their ability to withstand high temperatures without degrading ensures that researchers can maintain the integrity of their samples while achieving effective mixing.

Moreover, the smooth surface of PTFE stirring sticks minimizes contamination risk, making them preferred tools for precision applications in analytical and medicinal chemistry. Their durability means they can be cleaned and reused multiple times, which not only enhances sustainability practices in labs but also reduces costs over time. By selecting the right PTFE stirring stick based on your specific laboratory needs, including length and diameter suitable for your containers, you can significantly improve the accuracy and efficiency of your experiments.

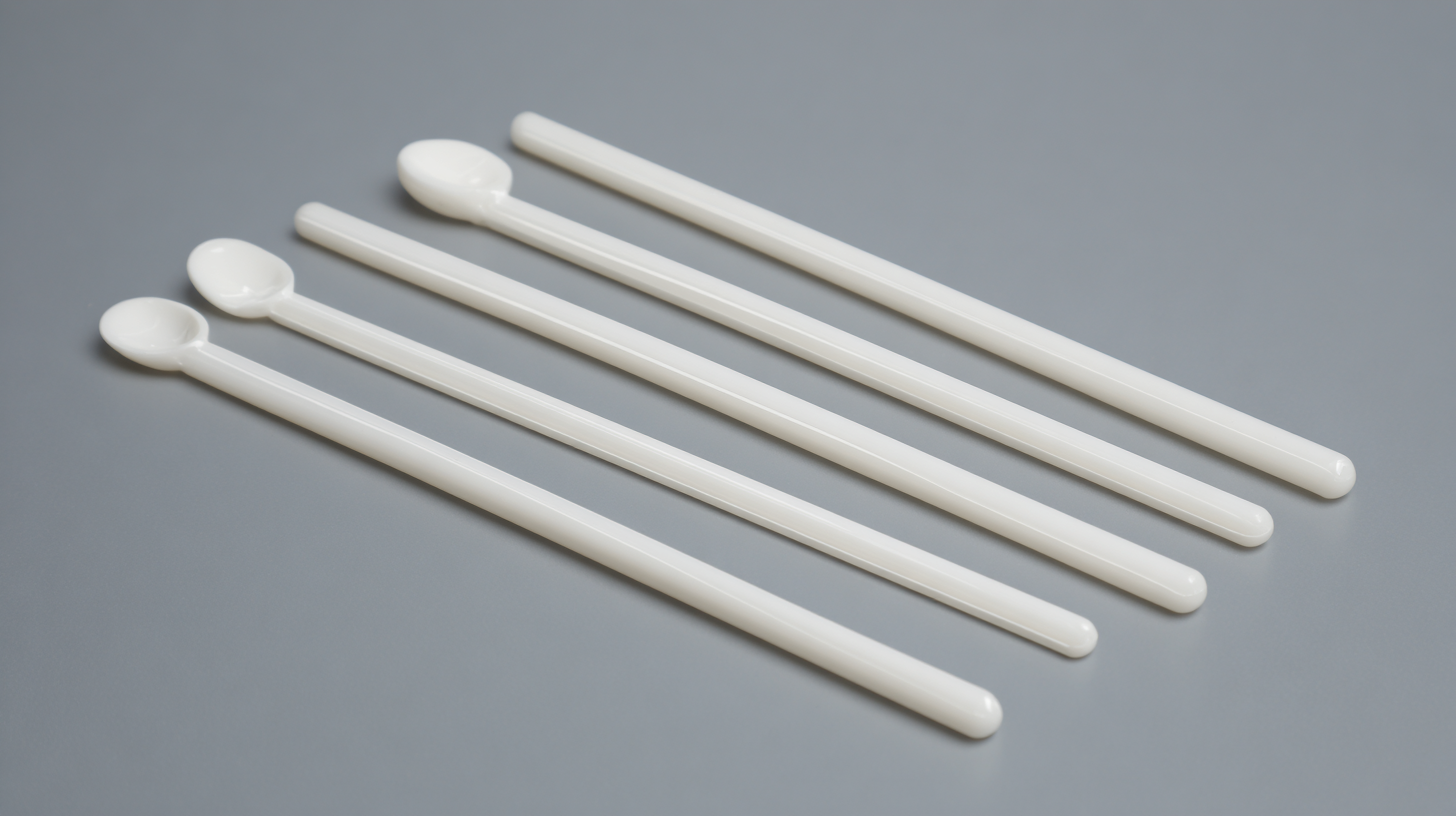

When choosing the best PTFE stirring stick for your laboratory needs, there are several key features to consider. Firstly, the size and length of the stirring stick are crucial factors. Depending on the types of containers and volumes you work with, a longer stirring stick may be necessary for deep vessels, while a shorter one could suffice for smaller beakers. Additionally, ensure that the stick's diameter is appropriate for your mixing requirements to achieve optimal stirring efficiency.

Another important attribute to look for is the stick's chemical resistance. PTFE, or polytetrafluoroethylene, is known for its durability and ability to withstand a wide range of harsh chemicals. However, not all PTFE products are created equal. Verify that the stirring stick you choose is specifically designed for your laboratory’s chemical environment to prevent any potential degradation or contamination. Lastly, consider the ergonomic design of the stirring stick. A comfortable grip can make a significant difference during prolonged use, enhancing your overall laboratory experience and productivity.

When selecting a PTFE stirring stick for laboratory use, it's essential to consider the specific applications you need it for. Different types of PTFE stirring sticks are designed to cater to various chemical properties and viscosities. For example, a tapered stirring stick may be suitable for precise mixing of small volumes, while a wider design facilitates the mixing of larger quantities more efficiently. Testing different designs in your lab setting can provide insights into which type meets your performance requirements best.

Tips: Ensure the PTFE stirring stick you choose is compatible with the chemicals you are working with. Using the wrong type can lead to unintended reactions or degradation of the stick. Additionally, consider the stick's length relative to the vessel's depth to optimize functionality. A longer stick can reach deeper into vessels, but always weigh this against ease of handling and storage.

Another critical aspect is the surface texture of the stirring stick. Some may prefer a smooth surface for easy cleaning and maintenance, while others might find a slightly textured surface provides better mixing by creating turbulence in the solution. Experimenting with different finishes may help you find the best option for your laboratory tasks.

When choosing the best PTFE stirring stick for laboratory needs, evaluating durability and chemical resistance is crucial. PTFE, or polytetrafluoroethylene, is renowned for its exceptional chemical resistance and non-stick properties, making it an ideal choice for laboratory applications involving reactive substances. The latest advancements in materials demonstrate the development of high-strength nanocomposites, like PBO nanofiber-polytetrafluoroethylene, which offer an impressive tensile strength of 271.6 MPa—an increase of 52.9%—enhancing the durability of stirring sticks even further. Such materials can withstand harsh laboratory environments while maintaining structural integrity.

Additionally, the potential for contamination from PTFE-coated items has raised concerns within the scientific community. Research indicates that microplastics and PTFE from cookware can leach into food, posing risks related to health and safety. Though PTFE stirring sticks generally perform better under controlled conditions, it's essential to source products that guarantee high chemical resistance and low risk of releasing harmful particles. Hence, opting for high-quality PTFE stirring sticks made from advanced composite materials will not only provide superior performance but also mitigate possible contamination issues in laboratory settings.

| Stirring Stick Diameter (mm) | Length (cm) | Chemical Resistance (Strength) | Durability Rating (1-5) | Recommended Use |

|---|---|---|---|---|

| 6 | 25 | Excellent | 5 | General laboratory use |

| 8 | 30 | Very Good | 4 | Viscous solutions |

| 10 | 35 | Good | 3 | Corrosive materials |

| 12 | 40 | Moderate | 4 | High temperature applications |

| 14 | 45 | Excellent | 5 | Heavy-duty mixing |

When selecting the right PTFE stirring stick for your laboratory mixing needs, size and shape play critical roles in ensuring effective and efficient mixing. A study by the Journal of Chemical Education indicates that using appropriately sized stirring sticks can improve the mixing efficiency by up to 30%. The correct diameter should align with the volume of the container; for instance, a 5mm diameter stick is ideal for smaller beakers, while larger volumes may require a stick of 10mm or more.

Tips for choosing the right stirring stick include considering both the viscosity of the materials you'll be mixing and the depth of your containers. A longer stick may be necessary for deep flasks, as it can reach the bottom and facilitate a more thorough mixing. Additionally, shapes matter; for instance, a flat-ended stick can create a more uniform mixing action in viscous solutions while minimizing the potential for splashing. Moreover, selecting a flexible stick offers the advantage of better maneuverability in narrow openings.

Remember to review the chemical compatibility of the PTFE material with the substances you’re working with, as this can affect both the longevity of your stirring stick and the integrity of your samples. Keeping these considerations in mind will ensure optimal performance in your laboratory mixing processes.