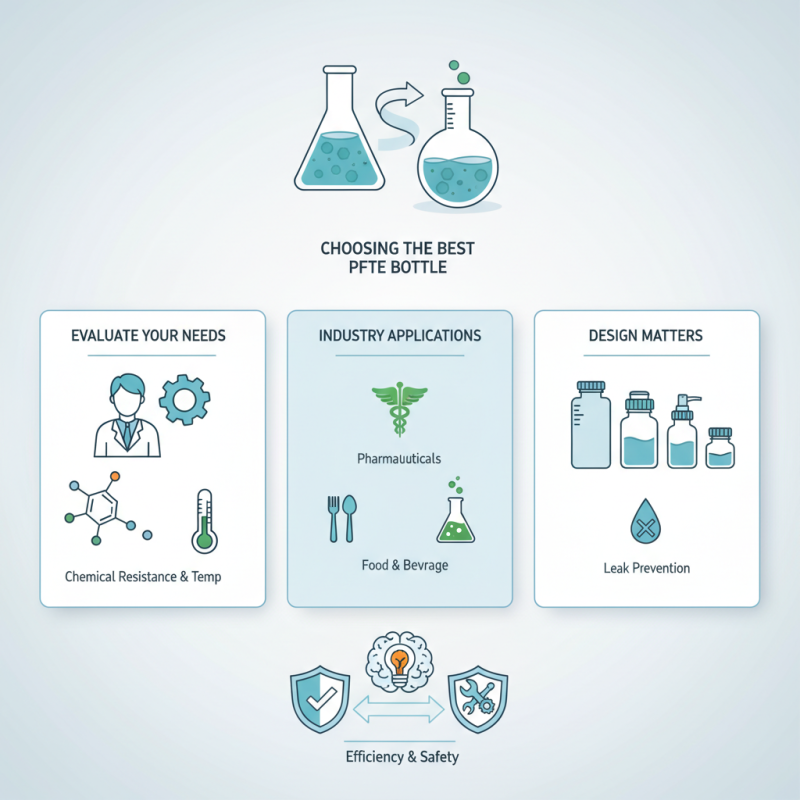

When considering a PTFE bottle, it's essential to evaluate your specific needs. Dr. Emily Tran, a leading expert in polymer materials, emphasizes, "Choosing the right materials can significantly enhance performance and safety." PTFE, or polytetrafluoroethylene, is known for its exceptional chemical resistance and non-stick properties.

Selecting the perfect PTFE bottle involves understanding its applications. Different industries, from pharmaceuticals to food, demand specific features. For instance, laboratory settings often require bottles that can withstand high temperatures and harsh chemicals. A mismatch can lead to failures, leading to costly repercussions.

It's also important to consider design aspects, such as size and closure type. Not all PTFE bottles are created equal; variations can affect usability. Pay attention to details like spouts and seals to prevent leaks. While the choices may seem overwhelming, an informed decision can lead to better efficiency and safety in your projects.

Understanding PTFE is essential for choosing the right bottle. PTFE, or polytetrafluoroethylene, has unique properties. It is known for its excellent chemical resistance. This makes it ideal for various applications. PTFE bottles can withstand harsh conditions and aggressive substances. They are commonly used in laboratories and industrial settings.

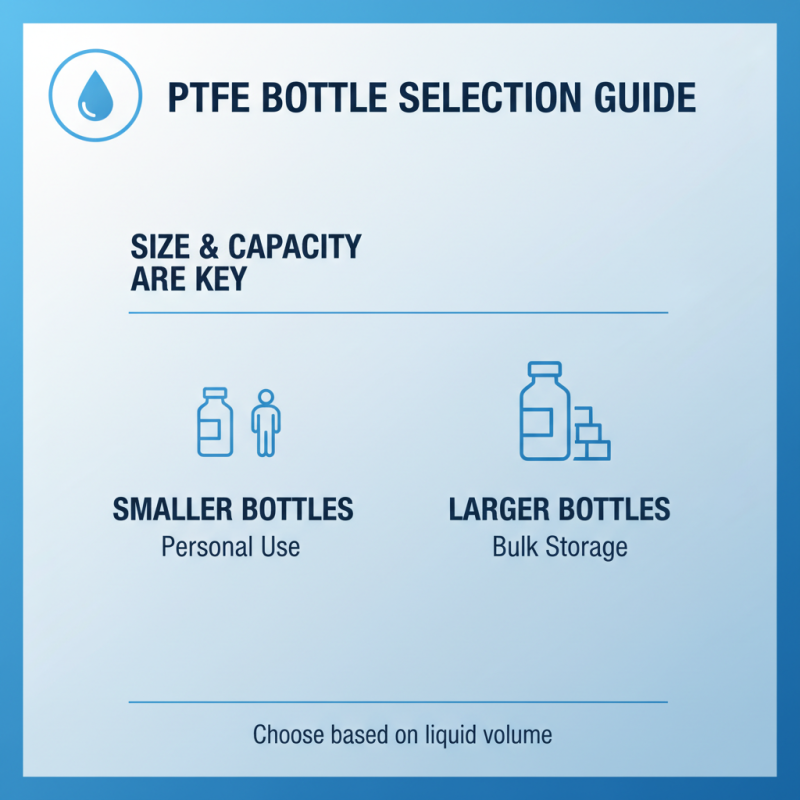

When selecting a PTFE bottle, consider its sizing. Choose a size that fits your specific needs. A bottle too large might just waste space. A smaller bottle may require frequent refills. Think about how often you will use the bottle. This will guide your decision. Remember that weight can vary with size.

Tips for choosing:

- Check the temperature range. Some PTFE bottles handle high temperatures better.

- Assess the seal quality. A tight seal prevents leaks.

- Look for easy-to-clean designs. This saves time and ensures safety.

Keep in mind that not all PTFE bottles are created equal. Some may not hold up well over time. Always test a new bottle with your specific substances before full use. This ensures compatibility. Evaluating your choices can lead to better long-term satisfaction.

When selecting a PTFE bottle, several factors come into play. One crucial aspect is the size of the bottle. Consider your usage needs. A small bottle may suffice for minimal tasks, while larger capacities are ideal for more extensive applications. The weight of the bottle also matters. Lightweight options are easier to handle, especially in laboratory settings.

Another vital factor is the bottle's design. Look for features like a secure cap or spout that facilitates pouring without spills. Some bottles have graduated markings, helping you measure accurately. Additionally, consider the temperature tolerance. Ensure the bottle can withstand the temperatures you plan to use it for.

Lastly, think about compatibility with chemicals. PTFE bottles are generally resistant, but some substances may affect performance. It's important to reflect on potential interactions before making a choice. A detailed review of your specific needs can prevent future inconvenience. Ultimately, the right bottle should meet your practical requirements while providing reliability.

When selecting a PTFE bottle, various designs and features come into play. One must consider factors like chemical resistance and temperature tolerance. A study by the American Chemical Society states that PTFE bottles are highly resistant to aggressive solvents, making them suitable for many applications. Users should assess how these bottles will be used in their specific environments.

Different PTFE bottle styles offer unique advantages. Some designs feature ergonomic handles, enhancing grip during use. Others might include wide openings for easy cleaning. According to a recent industry report, nearly 40% of users prioritize design over functionality. This highlights a striking gap in the market, showing that manufacturers need to be innovative yet practical.

When evaluating PTFE bottles, look for certification marks. These ensure that the product meets necessary quality standards. Features such as leak-proof seals can greatly affect performance. However, not all bottles with seals are equally effective. Users have reported inconsistencies in seal reliability. This indicates a need for ongoing product testing and feedback from consumers. Consider these aspects carefully before making a purchase.

When selecting a PTFE bottle, size and capacity are vital. These factors ensure the bottle meets your specific needs. Consider how much liquid you will store. Smaller bottles work well for personal use. Larger ones are better for bulk storage.

Tips: Measure the space where you’ll store the bottle. Will it fit in your cabinet? Check the dimensions and be honest about your space.

Choosing the right capacity also depends on usage frequency. If you only need a small amount occasionally, a compact model is ideal. For everyday activities, a larger capacity may save you time. Think about your workflow. Are you constantly filling? A larger bottle may help streamline your process.

Tips: Look at the weight of a filled bottle. A heavier bottle may become cumbersome to handle. Reflect on what works best for you.

Proper maintenance is crucial for extending the life of PTFE bottles. Studies indicate that regular cleaning can enhance the bottle's performance and hygiene. A simple method involves rinsing with warm water and mild soap after each use. This helps prevent the buildup of residues. Users often overlook this step, leading to decreased functionality over time.

Storing PTFE bottles correctly is equally important. Keeping them in a cool, dry place protects against degradation. Avoid exposing them to direct sunlight for long periods. Research shows that UV exposure can weaken the material. Failing to follow this guideline may result in cracks or leaks.

While PTFE is generally durable, mishandling can cause noticeable wear. Gentle handling during transport reduces the risk of physical damage. Many users assume PTFE is completely indestructible, but this is not entirely true. The right approach to care can make a significant difference. A little attention goes a long way in preserving the integrity of your PTFE bottles.