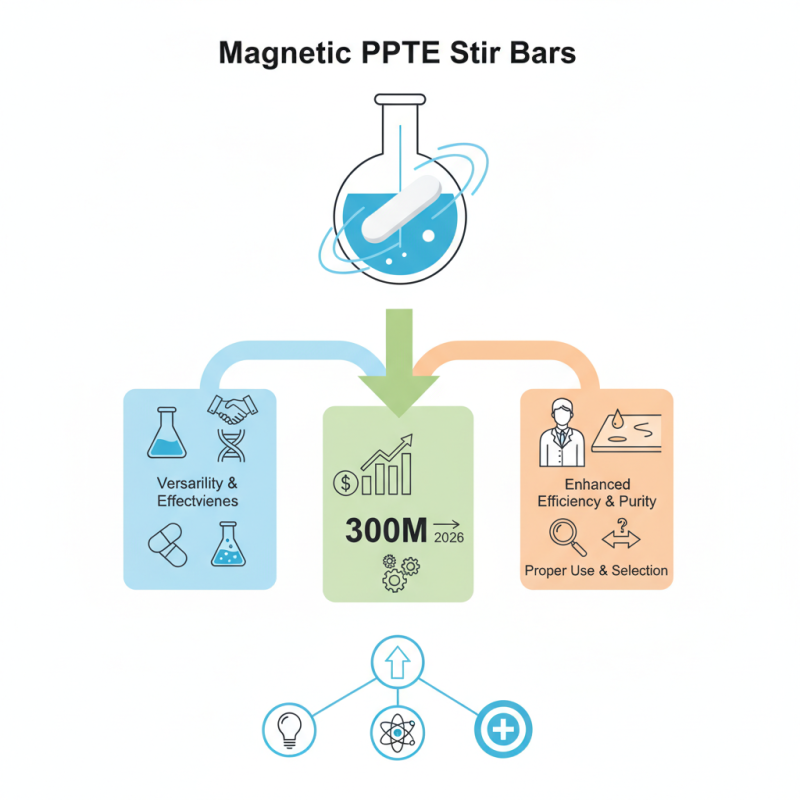

Magnetic PTFE stir bars have gained significant traction in laboratory settings due to their versatility and effectiveness. According to a report by Research and Markets, the global magnetic stirrer market is projected to reach $300 million by 2026. This growth highlights the increasing reliance on efficient mixing solutions in various industries, including pharmaceuticals and chemicals.

Dr. Emily Carter, a chemical engineering expert, stated, "The proper use of Magnetic PTFE stir bars can enhance reaction efficiency while reducing contamination risks." These stir bars are particularly advantageous in sensitive applications where chemical reactivity and purity are critical. Their non-stick surface allows for easy cleaning, making them a practical choice for labs focused on maintaining high standards.

Despite their benefits, some users may not fully leverage the capabilities of Magnetic PTFE stir bars. Factors such as improper sizing and incorrect stirring speeds can lead to suboptimal results. It's essential for researchers to understand how to select and utilize these tools effectively to maximize their potential. Exploring the best uses and benefits of Magnetic PTFE stir bars can lead to enhanced productivity and innovation in scientific work.

Magnetic PTFE stir bars are essential laboratory tools. They consist of a magnetic core and a PTFE coating. This design allows for smooth mixing without contamination. The PTFE material also resists chemicals and withstands high temperatures. Many researchers prefer these stir bars for their durability.

Their primary function is to create a magnetic field for stirring liquids. As a magnetic stirrer rotates, the stir bar follows. This creates a vortex, ensuring even mixing. The non-stick surface of PTFE prevents reactions with most substances. However, they can wear over time and may require replacements.

One challenge with magnetic PTFE stir bars is visibility. They can be difficult to see in opaque liquids, making monitoring harder. Additionally, some users might struggle to position the stir bar correctly. These issues can lead to inconsistent results. However, with careful handling, their benefits often outweigh the drawbacks. They remain a popular choice in many labs globally.

Magnetic PTFE stir bars are widely used in laboratories for their unique advantages. They consist of a strong magnetic core coated in PTFE, a chemically resistant material. This coating ensures that the stir bars can mix a variety of solutions without contaminating them. Users appreciate how these stir bars can withstand harsh chemicals. They resist corrosion and react minimally with solvents.

One notable benefit is ease of cleaning. After use, researchers can simply rinse the stir bar without much hassle. However, sometimes residue still clings to the surface. A deeper clean might be necessary, yet this is often overlooked. Besides, some users find that they misplace these tiny tools easily. Using a designated storage container could help solve this issue.

Magnetic stir bars also offer convenience. They enable smooth and consistent mixing without needing manual assistance. This is particularly helpful when conducting experiments requiring precision. Yet, it’s essential to ensure they are the right size for the vessel. If too small or too large, mixing efficiency can drop significantly. These details highlight the practicality and challenges of using magnetic PTFE stir bars.

| Use Case | Benefits | Application Areas | Material Compatibility |

|---|---|---|---|

| Mixing Chemical Solutions | Uniform mixing without contamination | Chemical laboratories | Acids, bases, organic solvents |

| Emulsification | Enhanced stability of emulsions | Biotechnology | Hydrophilic and hydrophobic phases |

| Reactions in Viscous Mediums | Improved efficiency in thick solutions | Food and pharmaceuticals | High viscosity substances |

| Temperature Sensitive Experiments | Minimal heat transfer | Clinical research | Heat-labile compounds |

| Agitation in Synthetic Processes | Consistent reaction conditions | Chemical synthesis | Various solvents |

Magnetic PTFE stir bars are widely used in various laboratory experiments due to their unique properties. These stir bars, coated with polytetrafluoroethylene (PTFE), resist chemical reactions and wear. This makes them ideal for mixing solutions that may be corrosive or reactive.

In chemistry labs, magnetic PTFE stir bars efficiently mix solutions while minimizing contamination. Their non-stick surface ensures easy cleaning and prevents residues from sticking. Researchers often rely on them to create homogenous mixtures, whether for reagent preparation or sample analysis. Their ability to withstand a wide range of temperatures means they can be used in heated reactions too.

However, there are challenges in using these stir bars. Sometimes, they can magnetically adhere to the stirrer, making retrieval difficult. Users must watch for this to avoid losing the stir bar in a reaction vessel. Additionally, while they are effective, adjusting the stirring speed becomes essential. Too fast, and it may create vortices that can lead to air entrapment. Finding the right balance can be a learning curve for many researchers.

Maintaining the quality of PTFE stir bars is essential for optimal lab performance. Start by rinsing the stir bars with water after each use. Dust and residue can cling to the surface, affecting the effectiveness. A gentle soap solution can help remove stubborn residues. Avoid abrasive cleaners. They can scratch the PTFE surface, which may lead to contamination during experiments.

Storage also plays a vital role. Always store PTFE stir bars in a dry place. Humidity can damage the material over time. Using dedicated containers can keep them safe from dust and physical damage. Check the stir bars regularly for signs of wear. Microscopic cracks can form, indicating that it's time for replacement. Small details matter a lot in laboratory work. Neglecting minor damage can lead to inaccurate results.

Routine inspection of the stir bars is crucial. Look for discoloration or unusual textures. These are signs they need special attention. Consider keeping a maintenance log to track your stir bars' condition. Reflecting on their use will ensure the longevity and efficiency of your equipment. Don't overlook the importance of proper care. Taking these steps will lead to better experiment outcomes and a more reliable work environment.

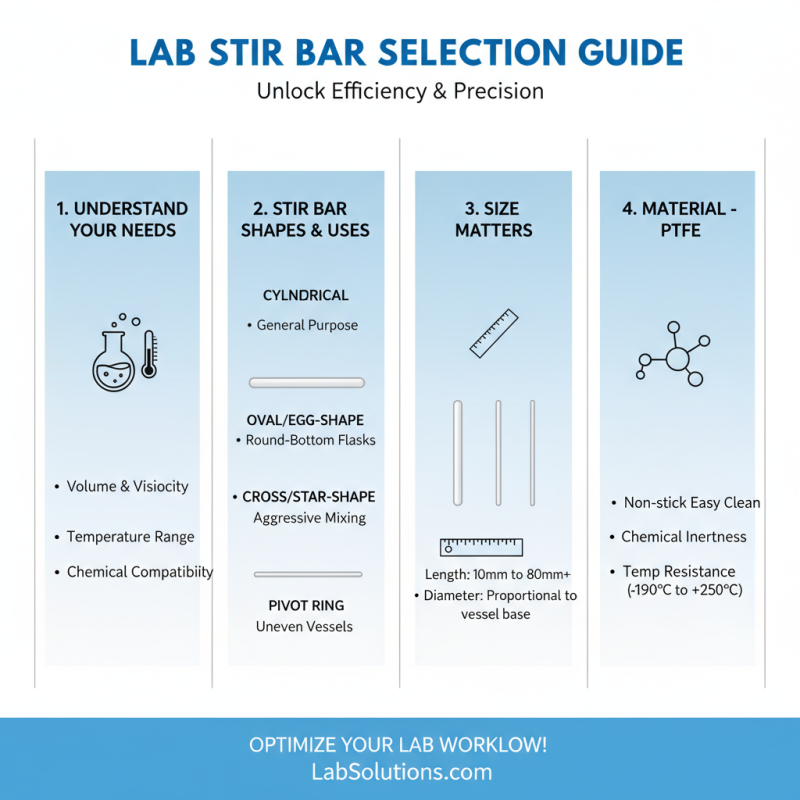

Choosing the right magnetic PTFE stir bar can significantly improve your lab experience. Many options exist, each designed for specific tasks. Understanding your needs is crucial.

Consider the size and shape of the stir bar. A long, narrow bar works well in smaller vessels, while a larger diameter is better for bigger containers. The material consistency is also important. PTFE offers excellent chemical resistance, yet not all bars are created equal.

Some stir bars may not provide strong enough magnetic attraction. This can lead to ineffective mixing. It’s worth assessing the viscosity of the liquids you’ll be working with. High-viscosity liquids may require a more robust stirring mechanism. Think about your experiments and the conditions they involve. Making the wrong choice might lead to unexpected challenges. Don’t overlook these details; they can make or break your results.