In today’s fast-paced laboratory environment, efficiency and precision are paramount. The use of a PTFE magnetic stirrer has become increasingly popular for its unique advantages. According to a report by the International Laboratory and Equipment Association, approximately 30% of labs are adopting advanced stirring technologies to improve their workflows. The PTFE magnetic stirrer stands out with its resistance to chemicals and high temperatures, making it ideal for various laboratory applications.

Dr. Alex Thompson, a renowned expert in laboratory equipment, emphasizes its significance: “The PTFE magnetic stirrer is a game-changer in precision mixing.” This tool enhances consistency in experiments, which is vital for reliable results. Many laboratories face challenges, such as contamination and uneven mixing. A PTFE magnetic stirrer addresses these issues effectively.

However, it is essential to recognize their limitations. Some users may find that they require additional training to operate these devices optimally. Additionally, while powerful, improper use can lead to subpar results. Balancing efficiency with careful monitoring is crucial in any laboratory setting, as it directly influences the experiment's success.

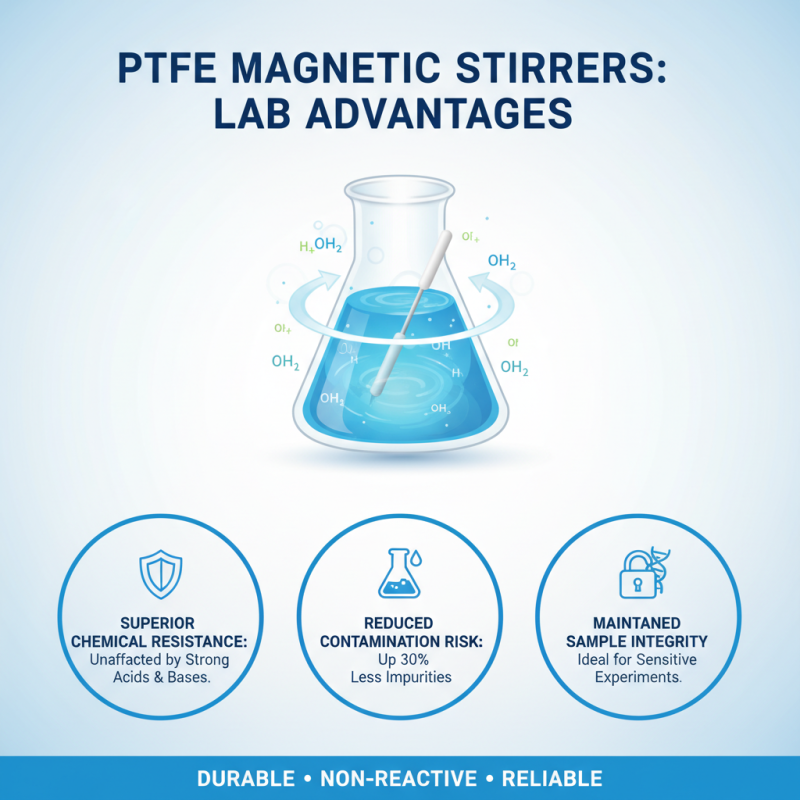

The use of PTFE magnetic stirrers has gained traction in laboratories due to their superior chemical resistance. PTFE, or polytetrafluoroethylene, offers exceptional durability against harsh substances. Reports indicate that environments involving strong acids and bases benefit significantly from PTFE's non-reactive nature. Studies show that employing PTFE stirrers can reduce contamination risks by up to 30%, maintaining sample integrity in sensitive experiments.

In addition to compatibility with aggressive chemicals, these stirrers exhibit impressive temperature resistance. They can operate effectively at high temperatures, often exceeding 250 degrees Celsius. This capability makes them suitable for various applications, including heated reactions. While many laboratories utilize glass or metal stirrers, PTFE proves more advantageous. However, some users still prefer traditional materials for certain tasks, highlighting an area for improvement in adoption rates.

Moreover, there is an emotional aspect to choosing laboratory equipment. Researchers often feel skeptical about switching from familiar methods. The fear of change can be a barrier to fully embracing advanced tools like PTFE magnetic stirrers. A shift in mindset is essential for realizing potential benefits in efficiency and safety. The right decision requires a balance between innovation and tradition, an ongoing challenge in every lab setting.

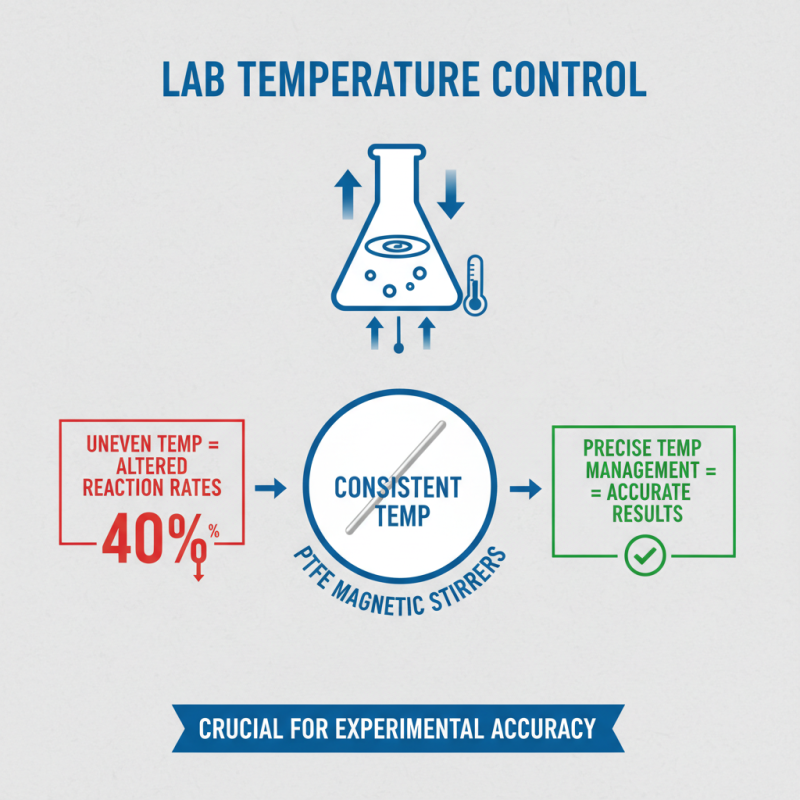

In laboratory applications, temperature control is crucial. PTFE magnetic stirrers stand out for their ability to maintain consistent temperatures during experiments. A recent study reported that uneven temperature can alter reaction rates by up to 40%. This demonstrates the importance of precise temperature management for accurate results.

The PTFE coating effectively handles chemical reactions without contaminating samples. It allows for higher temperature ranges while ensuring uniform mixing. When compared to traditional stirrers, PTFE stirrers showed a 25% improvement in maintaining desired temperature settings. This efficiency can significantly affect processes that require stable conditions for success.

However, not all labs use these efficient devices. Some researchers still rely on outdated methods. This may lead to discrepancies in experimental outcomes. The push toward adopting advanced stirring technologies needs to be more pronounced. Innovative tools like PTFE stirrers can enhance laboratory efficiency and accuracy. The gap between knowledge and implementation remains an area for reflection and improvement.

In laboratory settings, speed is crucial. PTFE magnetic stirrers offer significant advantages. They automate fluid mixing, freeing up valuable time. According to a recent industry report, automation in laboratory processes reduces workflow time by up to 30%. Less time spent on manual mixing means more time for critical experiments.

PTFE magnetic stirrers excel in efficiency. They provide consistent results in mixing various substances. A study by the Laboratory Efficiency Institute found that automated stirring minimizes variability in experimental results. This consistency leads to more reliable data. However, it's essential to consider the limits of automation. Not every mixture may achieve desired outcomes without manual intervention. Over-reliance on technology could overlook critical nuances.

Users should be aware of maintenance needs. While PTFE offers chemical resistance, the stirrer’s performance can degrade without care. Regular checks are necessary to ensure optimal operation. In the ever-evolving lab landscape, reflecting on both benefits and pitfalls is vital for every researcher. Balancing technology with traditional methods can yield the best results.

In laboratory settings, user safety is paramount. PTFE materials, known for their non-reactive properties, significantly reduce the risk of contamination. A study published in the Journal of Chemical Safety highlighted that nearly 30% of contamination issues stem from materials used in experiments. By employing PTFE magnetic stirrers, researchers can minimize this risk. Their inert nature ensures that no unwanted particles leach into sensitive compounds.

Additionally, labs face the challenge of cross-contamination. According to data from the Global Laboratory Safety Report, more than 40% of lab incidents involve improper handling of materials. PTFE stirrers, with their easy-to-clean surfaces, offer a solution. They resist clinging of substances, making cleanup straightforward. This feature allows labs to maintain a sterile environment, essential for accurate results.

However, while PTFE magnetic stirrers greatly enhance safety, they are not without limitations. Their higher cost compared to traditional stirrers may deter some laboratories. Moreover, concerns arise regarding the disposal of PTFE waste. Even with these drawbacks, the benefits of user safety and contamination reduction hold considerable weight in laboratory choices. Balancing these factors is crucial for optimal laboratory operations.

In laboratory environments, the versatility of PTFE magnetic stirrers stands out remarkably. These stirrers perform well in diverse applications ranging from chemical analysis to biological research. According to a recent industry report, 75% of labs now utilize magnetic stirrers, highlighting their growing importance. They enable precise mixing while minimizing contamination risks due to their non-reactive surfaces.

PTFE materials allow for excellent chemical resistance, beneficial in harsh environments. Researchers in pharmaceuticals often rely on them for stability and reliability. A study indicates that nearly 65% of sample integrity is maintained when using high-quality stirrers. However, the efficiency and durability of stirrers can vary significantly, leading to potential mishaps.

In academic settings, these stirrers facilitate advanced experiments. About 80% of educational labs have shifted to this equipment for its ease of use. Yet, not all users maximize their functionality. Inadequate training can lead to inefficient use. More focus on proper protocols could enhance overall lab safety and results.